PUF Pipe Section Manufacturers in India – Fabmax Enterprises

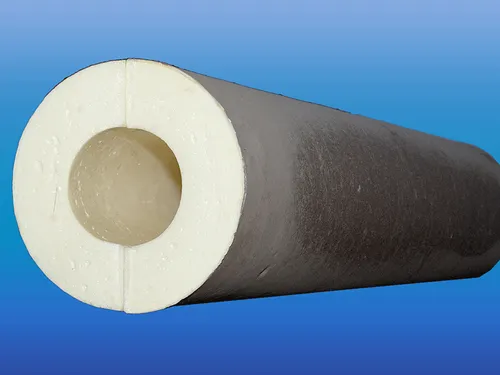

Fabmax Enterprises is a dominant PUF pipe section manufacturers, suppliers, exporters and fabricators in India. Our PUF Pipe Sections, or Polyurethane Foam Pipe Sections, are insulation materials used to reduce heat loss in pipelines.

They are made from polyurethane foam, a closed-cell structure that provides excellent thermal insulation. These sections are commonly used in industries like HVAC (heating, ventilation, and air conditioning), and in applications involving chilled water, hot water, and process pipelines.

Below, we have listed down its multiple types, it’s using benefits and applications as well!

PUF Pipe Section Types

As leading PUF pipe section manufacturers in India, we are providing the best quality of PUF Pipe Section such as:

-

Plain PUF Pipe Sections

Plain PUF Pipe Section is a budget-friendly thermal insulating product specially designed for exposure to light residential and commercial environments. Perfect usage for indoor pipe system installations with neither exposure to harsh weather conditions nor water exposure, the sections provide consistent insulation performance at cost-for-value costs. Simple install, lightweight, and a very good value as used in instances where temperature rates are regulated indoors in buildings.

-

Aluminium Foil Laminated PUF Sections

Our Aluminium Foil Laminated PUF Pipe Sections are suitable where radiant heat control and reflective insulation are required. They are utilized in industrial ducting systems and HVAC equipment and have the added thermal resistance advantage of the aluminium foil as well as protection against low-level physical attack, UV radiation, and dust. The laminate coating enhances the efficiency and durability of the Polyurethane Foam Pipe Section for high-temperature use.

-

GI & Aluminium Cladded PUF Pipe Sections

For application in outer pipelines and harsh industrial applications, we also provide Pre-Cladded PUF Pipe Sections in GI (Galvanized Iron), aluminium, or even Stainless Steel cladding. The claddings are mechanically wear-and-tear-resistant and corrosion-proof, thereby providing the longest pipeline life as well as insulation. Suitable for high humidity-exposed pipelines, fluctuation temperatures, or corrosive chemicals, the insulation is very usable in petrochemicals, water treatment, and food processing.

-

Fire-Retardant PUF Pipe Sections

We've engineered our Fire-Retardant PUF Pipe Sections with newly engineered fire-resistant materials that are built to international best safety standards. They're the first choice in high-risk environments like refineries, power plants, and chemical processing plants, where there's just no other option but fire protection. Even though fire-resistant, these sections don't suffer any loss of thermal insulation performance that you'd suffer in a quality Polyurethane Foam Pipe Section.

-

Eco-Friendly Bio-Based PUF Sections

Performance and sustainability converge in our Eco-Friendly Bio-Based PUF Insulation Pipe Sections. They are produced with partially renewable polyols that release significantly less carbon into the environment but have the same thermal and mechanical performance as traditional PUF. They are perfect for green-friendly projects and can make green building a reality without compromising on insulation reliability and performance.

Technical Features of our PUF Pipe Section

For more additional technical information, we have mentioned below a technical sheet such as:

| Parameter | Specification |

|---|---|

| Product Name | PUF (Polyurethane Foam) Pre-Insulated Pipe Section |

| Density | 36–40 kg/m³ (±2 kg/m³) |

| Thermal Conductivity (λ value) | 0.021–0.024 W/m·K at 10°C |

| Temperature Resistance | -180°C to +110°C (Continuous) |

| Compressive Strength | > 2.0 kg/cm² (ASTM D1621) |

| Water Absorption (Closed Cell) | < 2% by volume (ASTM D2842) |

| Cell Structure | Closed Cell > 90% |

| Thickness Range (Insulation) | 25 mm to 150 mm |

| Pipe Sizes Available | ½" to 36" NB (Standard and Custom Sizes) |

| Facing Options | Kraft Paper, GI Sheet, Aluminium Foil, Bitumen-coated |

| Fire Behavior | Self-extinguishing, B2 Class (DIN 4102) |

Key features of our PUF Pipe Section

Being the best PUF Pipe Section suppliers in India, these all types of PUF Pipe Section are made with multiple types of features inside such as:

-

High Thermal Efficiency (λ value ≤ 0.022 W/mK)

Our PUF Pipe Sections remain heat insulated under direct exposure to heat. That means lower energy use and less operation cost. Their increased insulation factor also increases infrastructure sustainability targets nowadays.

-

Closed-Cell Structure (~90–95%)

Since its closed cell foam content is heavy, such pipe sections are water-tight and will not deteriorate with insulation performance over time. This also prevents mold and maintains overall system cleanliness. It's an ideal attribute for temperature-sensitive or wet service applications.

-

Dimensional Precision

Due to CNC profiling every pipe piece will be an exact fit to the pipe diameter as specified with no space or air flow allowance. This gives thermal equality and the removal of stress points throughout the system. It gives a cleaner faster and more accurate installation.

-

Advanced Fire Safety Additives

All our Fire-Rated PUF panels are halogen-free and comply with international environmental and safety regulations. They are thus the perfect choice for mission-critical applications like cleanrooms healthcare and energy complexes. Fire protection is integrated into the product and not an afterthought.

Benefits of using our PUF Pipe Section

As dominant PUF Pipe Section fabricators in India, these all types of PUF Pipe Section are highly beneficial such as:

-

Energy Savings up to 40%

Our insulation solutions dramatically reduce energy loss across HVAC and fluid systems. That translates to lower utility bills and a reduced carbon footprint. Long-term, that translates to measurable ROI for commercial and industrial customers.

-

Sustainable & Green Building Compliant

Our Fabmax products are compliant with LEED and IGBC certifications and hence the best suited for green building. With our PUF Pipe Sections, companies can meet requirements within a period of environment compliance. They are our part of a bigger drive to support sustainable infrastructure.

-

Low Maintenance

Designed to last more than twenty years in the best of environments our insulation does not need hardly any maintenance at all. This cuts down replacement cycle and decreases maintenance costs. Whether a data centre or refinery you are providing stability for the long term.

-

Temperature Range: -200°C to +110°C

Our PUF Pipe Sections find application in a wide variety of applications ranging from cryogenic lines to hot water systems. The reason for such versatility is through the application of the latest resin systems that are temperature-stable at extreme temperatures. It enables us to enter niche industries without compromising on quality.

Applications of our PUF Pipe Section

Our all types of PUF Pipe Section are majorly used in multiple types of industrial sectors such as:

-

HVAC Systems (Chilled/Hot Water Lines)

Our products conserve energy and control processes in small and large-scale hydrocarbon pipeline transportation networks. They are widely used in commercial complexes, hospitals, and institutional complexes. Their uniform performance achieves uniform climate control for networks.

-

Oil & Gas Pipelines

We provide robust insulation for combustible products pipelines traversing rough terrain. With improved mechanical strength and chemical resistance, our solutions provide unequalled security. They are designed to operate even under desert and offshore conditions.

-

Cold Chain Infrastructure

Temperature integrity is crucial in the food processing Pharma and logistics sectors. Our PUF Pipe Sections are relied upon to provide consistent insulation to cold storage and transport pipes. They guarantee no loss or spoilage of product.

-

Refineries & Chemical Plants

These sectors require fire-resistant products with rigorous fire safety requirements. Our PUF fire-retardant solutions provide confidence in highly regulated environments. They help to provide business continuity against safety concerns.

One of the leading PUF Pipe Section manufacturers, suppliers, exporters, and fabricators in India, we as Fabmax Enterprises are offering high-performance PUF Pipe Sections, specially engineered to deliver superior thermal insulation for a wide range of piping systems.

These PUF Pipes made from rigid polyurethane foam with a closed-cell structure, our PUF pipe sections provide outstanding insulation efficiency, significantly minimizing heat loss and enhancing energy conservation in both hot and cold pipeline applications.

Contact us today for more information!

Frequently Asked Questions (FAQs)

PUF (Polyurethane Foam) is a rigid, closed-cell insulation material known for excellent thermal resistance and lightweight properties.

PUF pipe sections typically have a density ranging from 36 kg/m³ to 42 kg/m³, depending on insulation standards.

EPS stands for Expanded Polystyrene, used in pipe sections for lightweight and economical thermal insulation.

PIR (Polyisocyanurate) offers higher fire resistance and thermal performance than PUF, though both are used for insulation purposes.